Al-Burhan Group to supply high-tech railway welding machines to IRR

Al-Burhan Group has signed a deal with U.S. railway machine manufacturing firm Kershaw to design, build and deliver five sophisticated track welding machines to Iraqi Republic Railways (IRR). These latest high-technology machines will allow IRR to continue with its rapid programme of modernising and expanding Iraq’s railway network infrastructure. The custom built machines will be delivered over the next twelve months with IRR railway engineers expected to receive training in Europe on how to operate and maintain the machines. Al-Burhan Group has successfully delivered numerous heavy-duty railway construction and maintenance machines in the recent past and is proud to add this latest deal to its business portfolio.

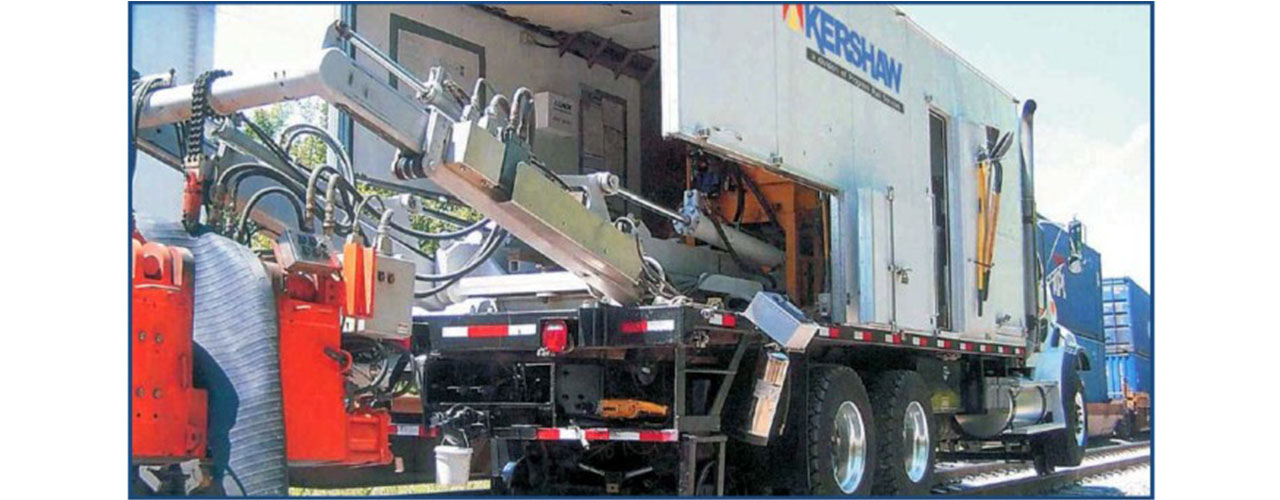

Kershaw is a subsidiary of Progress Rail Services Corporation (a Caterpillar company). The company has a long history of experience in designing and manufacturing rail welding equipment for over 50 years. Welding machines built by Kershaw have been utilised all over the world by major railroads. IRR through Al-Burhan had requested a new type of machine to consist of the latest welding head fitted onto a railway truck. This advanced design offers maximum flexibility and mobility allowing the machines to be quickly deployed anywhere along Iraq’s large and expanding railway network. Kershaw welding machines have been designed to match the capability of plant based machines allowing railway engineers to weld vast sections of track to a high standard in short amounts of time.

The welding machines from Kershaw have unrivalled capability in the railway industry. They are computer controlled and require a minimal amount of operator training. The self-diagnostic software installed on each machine allows users to accurately monitor and analyse previous welds to ensure optimal linkages between each iron section of track. The machines have built-in cellular connections allowing the factory in the U.S. to monitor and comment on any technical issues despite being thousands of miles away. The machines have been specifically designed to cope with the harsh dry and hot operating environment frequently experienced in Iraq. The self-propelled rail trucks onto which the welding machines are fixed onto allow easy transport from depot to work site. Such impressive machines are a world first and will allow IRR engineers to make use of the latest technology saving time and effort when working on the Iraqi railway network.