Introduction | Sleeper Factory | Daily Production Operations | Systems | Labs | History

Location

The Concrete Sleeper Factory is located in Abu Ghraib on the outskirts of the Capital, Baghdad. The factory’s central location was chosen to order to provide an advantage in distributing the finished product throughout the nation. The Concrete Sleeper factory is linked to the IRR network via a dedicated railway line that runs right inside the factory depot. This will allow for optimum delivery times to various locations throughout Iraq where track maintenance programmes are taking place.

General Info

Al-Burhan Group has taken a leading role in assisting IRR with its national programme of upgrade. The Group has recently brought back to operation; a Concrete Sleeper Factory in Abu Ghraib (pictured above) which will supply IRR with concrete sleepers for its network maintenance and expansion plans. The factory was originally constructed with the technical assistance of Dow-Mac (UK) in 1982. Following years of neglect, Al-Burhan Group took it upon themselves, to rehabilitate and modernise the facility bringing it back to full operation. |

|

This rehabilitation work was done with the assistance of RMS (UK) since the Dow-Mac company no longer exists. The concrete batching plant, originally supplied by SKAKO (of Denmark), was re-built using the old frame and SKAKO once more provided their machinery and expertise in re-building the plant. The factory currently consists of two production theatres capable of producing 2,800 sleepers per day. The aim is to eventually expand production levels to over 5,000 sleepers daily to match the ever increasing demand for railway materials in Iraq.

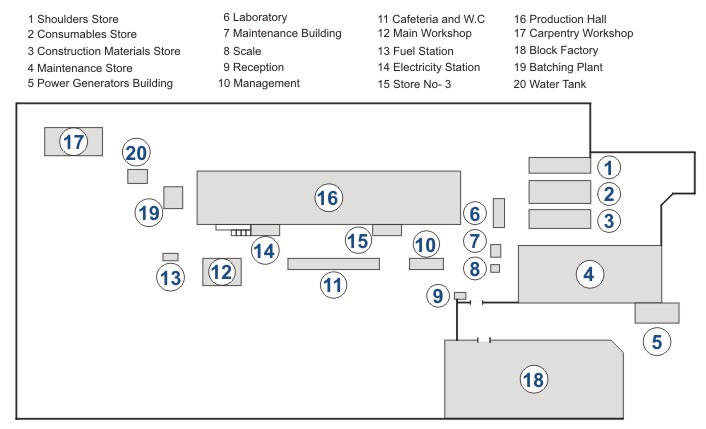

Picuted below is the layout of the factory which is surrounded by a high concrete wall. The factory consists of two main production theatres with a large depot for storing the finished product. In addition the factory has a railway line running directy inside allowing for efficient distribution of sleepers throughout the nation.

Factory Layout

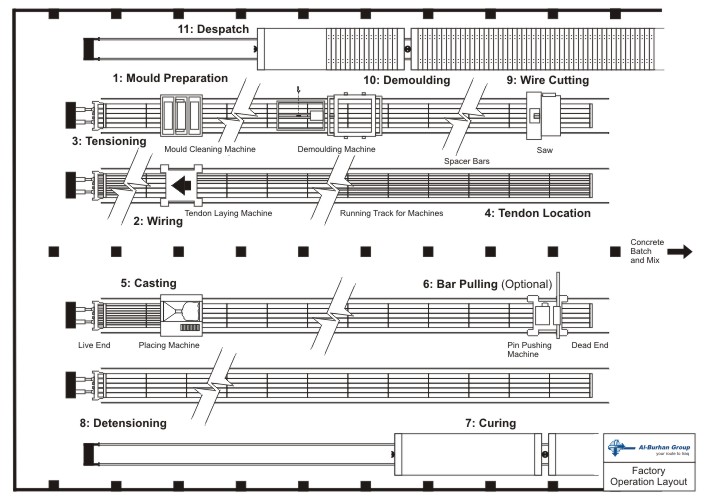

The diagram below (no. 16 above) dispalys the two production theatres which contain 10 production lines between them. A key area to note is preparation and casting areas where the majority of production takes place. Finished sleepers are removed from the production area and stored in the depot for three months (for final curing) prior to delivery.

Production Layout

Back to Top

|