Introduction | Sleeper Factory | Daily Production Operations | Systems | Labs | History

Batching System | Production System | Stressing System | Curing System | Air System

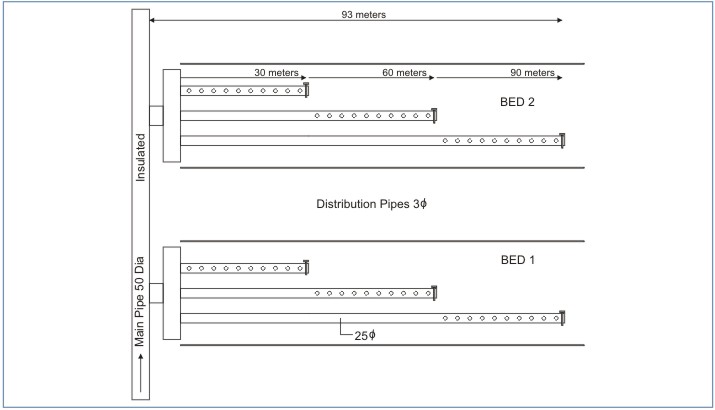

The steam curing system is powered by a pair of Thermax ‘Shellmax’ boilers; one for each production theatre. After the day’s production ends, polythene covers are pulled over the cast sleepers, while a network of pipes and valves distributes the steam evenly over the sleepers. The covers ensure that a minimal amount of heat and moisture is lost to the atmosphere. The pipes have small holes drilled into them allowing the steam to spread throughout the moulds; they are fixed to the ground on brackets.

A key requirement for the curing system is the use of pure water free from contamination. The factory receives several deliveries of purified water each week to ensure the system is fed with water of sufficient quality; otherwise lime scale and other contaminants could adversely affect the system. The steam curing overnight ensures that the concrete is sufficiently settled maximising the life and quality of the sleepers.

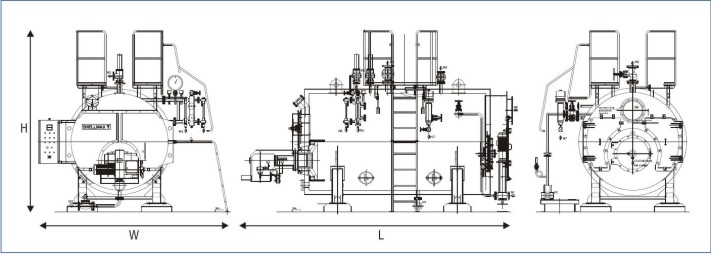

The Thermax ‘Shellmax’ boiler

An illustration showing the distribution of the steam curring system.

Back to Top

|